2 am Call

Honorable Mention in the March-April 1998 round of the IRTC

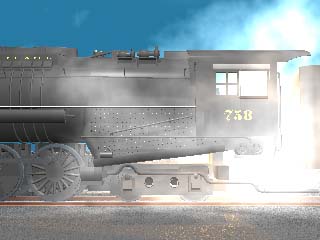

Nickel Plate Road engine terminal

Bellevue, Ohio,

January 7, 1957, 1:45 am

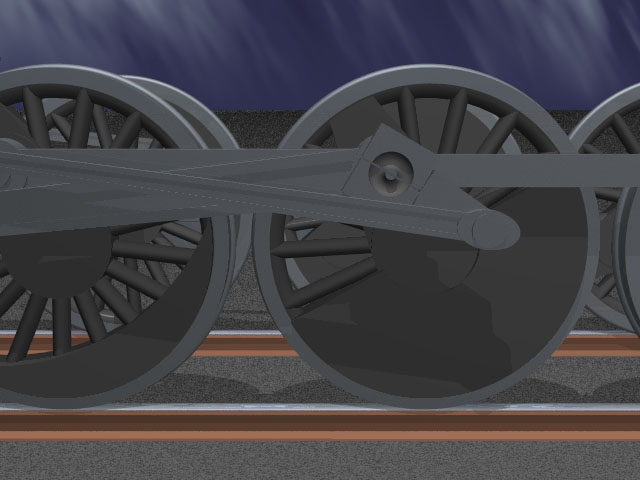

The snow has stopped for a while, although some has drifted across the

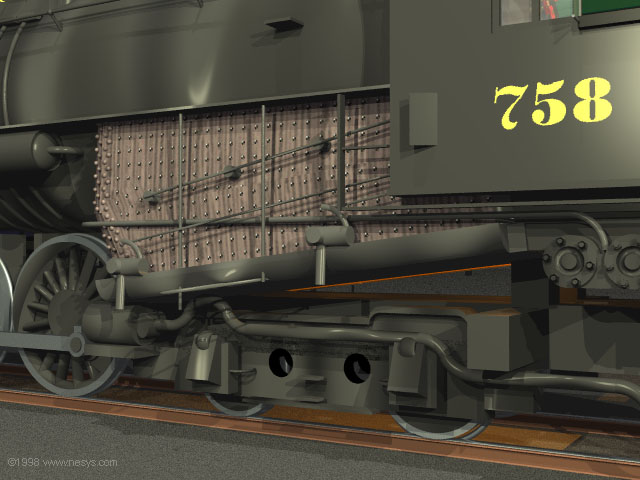

tracks. The hostlers are getting NKP 2-8-4 758 ready for an eastbound

perishable train, 85 cars of frozen beef for the eastern markets, crew

called for 2 am. The cargo is worth well over a million dollars, and any

delay means missing the markets in New York City and Boston,

and possible loss due to spoilage.

The 758's steam gage is showing 215 pounds, but climbing nicely, and by the

time the outbound crew arrives, they will have a hot, clean engine to

work with. Someone is working on 763's fire while waiting for the tender

water tank to fill, casting an orange glow across the scene.

Steam locomotives, like ships, have individual personalities.

The 763, on the left, was considered the queen of the fleet,

the easiest to keep hot, and always easy riding.

The 758, 742, and 763 don't have much snow on them, because they

haven't been in the terminal long, and won't be sitting there much longer.

They will all be back out on the road earning revenue within the hour.

Average idle time for servicing and turning these engines was under

1.5 hours, due to low-maintenance design and planned work flow.

758's train pulled in from Kansas City a few minutes ago with the 765,

and is currently being spotted at the ice plant across the yard, to get the

ice bunkers topped off. In this weather, it doesn't take much ice, but it's

cheap insurance with a cargo this valuable.

The engine will run straight through to Buffalo, NY, with a quick stop in

Cleveland to set out a few cars for the Northern Ohio Food Terminal, and at

Conneaut, Ohio to change crews, grease the crankpins, and take on coal

and water. In Buffalo, the Lackawanna RR will take over for the rest of

the journey east.

Speed limit for freight trains on the line was 60 mph, about 100 kph.

Due to the high speeds, and the many unprotected road crossings on the

line, these engines were equipped with Mars lights (invented by a man

named Mars, the owner of the Mars candy company), which oscillated in a

horizontal figure 8 (infinity) pattern. The drive motor could also be

stopped, for use as an extra headlight. The insides of the bells were

painted red, so they would flash red as the bell swung.

Day or night, the engines were quite intimidating.

At about the same time the Mars lights were added, most of the old bulb

headlights were retrofitted with dual sealed beam headlights, as seen on

the 763. The 742, under the coal dock, still has the old style headlight.

The additional electrical load of the extra lights and radio, and in some

cases, Automatic Train Stop or ATS, which stopped the train if it passed

a red signal, required the use of 2 or 3 turbogenerators, instead of the

normal single unit.

The Bellevue coal dock was somewhat unusual.

NKP favored cylindrical, rather than square coal docks.

This monster could handle 4 engines simultaneously.

The model presented here has been compromised slightly. The actual dock

was taller than shown, but has been shortened slightly to fit in the scene.

Note the lines left in the concrete by the wooden forms.

Railroading has been a true 24 hour business since the 1850's, with

nearly equal train density day and night.

Railroads pioneered many of the early advances in lighting, and developed

early signaling and communications technology for safe operation in

reduced visibilty and at night.

The Nickel Plate Road

The New York, Chicago and St. Louis Railroad, always known as theNickel Plate Road, was a smaller road which flourished in competition

with its much larger parallel rival, the New York Central System,

by pioneering, in the 1920's, scheduled fast freight service, with

guaranteed delivery times, an idea which is still novel to many companies.

The company turned liabilities into assets, realizing the need to

maximize utilization of their small physical plant, keeping trains moving

instead of sitting in yards, and minimizing delays out on the line.

The company devised a bonus system which rewarded fast, safe operation.

The limitations of a single track main line were overcome by scheduling,

knowing where each train would be at any hour of day or night, and where

trains would pass each other.

The result was a highly efficient operation, which continues to this day

in much the same way, under the ownership of Norfolk Southern System.

Super Power

In the late 1920's, the Nickel Plate was one of the pioneers ofhorsepower and efficiency improvements in locomotives, by participating

directly with the locomotive manufacturers, primarily Lima Locomotive

Works in Lima, ("Lye-ma") Ohio, in designing and testing new

thermodynamic concepts.

The result was the 2-8-4, the first in a family of "Super Power" engines,

which represented a quantum leap from previous designs. The design was

known as the "Berkshire", after the Boston and Albany Railroad's mountain

line in Massachusets where the concept was first proved.

The center of this design was a much larger boiler and firebox than

previous engines, allowing continuous maximum horsepower output with

significantly reduced fuel and water consumption. The idea was to

overdesign the system, so that maximum output could be achieved without

strain. The boiler could produce more dry, superheated, high pressure

steam on a continuous basis than the cylinders could use. Superheating

means heating steam well past its boiling point. It continues to expand

as the water molecules get more energetic and further apart, resulting in

much more available horsepower per pound of fuel and water consumed.

The big firebox allowed a thinner firebed, which could burn more

efficiently. There were many thermodynamic and gas flow optimizations

throughout the design, with extensive use of laboratory model simulations.

The resultant design remained competitive with early diesels

until the late 1940's or early 1950's. Road reliability was about equal

to that of current diesels.

These were very "Technical" engines, with many external gadgets, and a

great deal of internal subtlety. Due to many automatic controls and power

assists, they were easier to operate than older, smaller locomotives.

Many of these engines were equipped with steam and signal lines to allow

them to be used in pulling heavy passenger trains.

The Nickel Plate engines lasted until 1958, and were planned to keep

operating for several more years, but fell to the 1958 business recession

and difficulty in obtaining spare parts.

These were the engines I grew up with, seeing and hearing them daily

until age 14. We've been to Bellevue many times, and have seen the

locations, engines, and events described here.

It wasn't originally supposed to be a snow scene,

but the drifts came out so nice...

Nickel Plate Road 2-8-4

Revised 17-May-1998

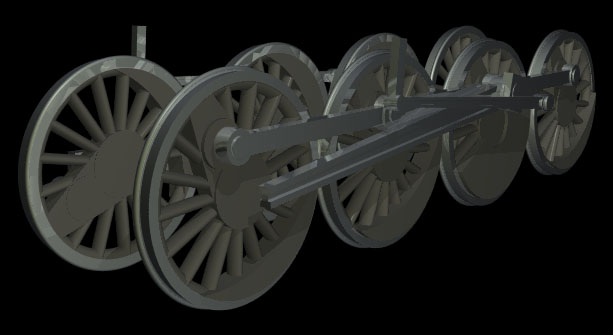

Before...

...After adding Flexible Staybolts

Weathering Notes

The generally grubby appearance of these engines in daily use was in sharpcontrast to the high quality of mechanical maintenance bestowed upon them.

The very fast turnaround times in the terminals and hard nosed economics

didn't allow much time for making them pretty.

The combination of grease, oil, soot, white sand for traction, and boiler

water treatment chemicals caused them to be a varied gray-brown color,

streaked with white. The areas of the fireboxes that were not covered with

lagging were normally a dark rusty color. Drivers were often nearly white

from traction sand, and tenders were usually a uniform dusty brown.

Additionally, parts were frequently spot painted in areas where repairs were

made, so that some parts might be shiny black, while the majority of the

engine was light brown. The boiler fronts were painted more frequently than

the rest of the engines, and the cabs were easier to clean and therefore

often contrasted with the overall appearance.

These engines differed from many others in that the smokebox was sheathed,

so that only the lower portion of the firebox was visible as bare metal.

The cabs were roomy, about 10 feet wide by 8 feet long, with a high arched

roof to let heat escape. The interior walls and ceiling were lined with

narrow wood wainscoting for insulation, painted a medium green.

There was provision to set a coffee pot on the backhead above the fire

door, and meals could be cooked using hot coals.

Combined with the polished brass gauges and valves, cozy fire, and subdued

electric lighting, the effect was that of an exclusive men's club,

which is exactly what it was.

Picture an airliner's cockpit, with a fireplace added.

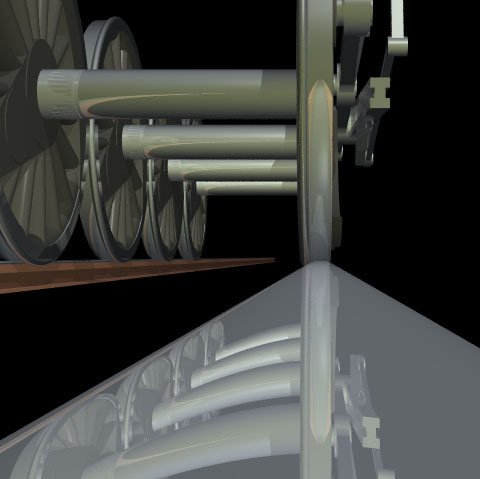

Weathering - Before and After

The cab interior still needs some work...

This is how it looks to a penny...

This is a work in progress. More details will be added.

Some early development work

Artwork (c) 1998 North East Systems